THIN DENSE CHROMIUM PLATING (TDC)

What is TDC?

TDC is a low-temperature, multistate process of electrocoating based upon chrome-plating technology. However, instead of using conventional chrome-plating solutions and parameters, the TDC process utilises a proprietary chemical solution. The solution and application process are carefully monitored to produce a very thin, dense chromium coating. TDC deposits a crack-free satin matte finish of 99.9% chromium on the base metal surface, whereas most conventional chrome-plating process deposits will be in the 82 to 88% chromium range.

The TDC process involves a special pre-cleaning and removing of the matrix on the basis metal's surface by special proprietary means followed by a modified electrocoating process that causes the chromium element of the TDC solution to permeate the surface porosity of the basis metal. It is during this process that the absolute adhesive characteristics and qualities of the TDC are generated.

The TDC coating actually becomes integrated with the metal itself. The result is a lasting bond and a continuous, smooth, hard surface. The surface will not chip, flake, crack, peel, or seperate from the basis metal on the standard ASTM bend tests or under conditions of extreme heat or cold. TDC can be applied to all ferrous and nonferrous metals, but is not recommended for aluminium, titanium or magnesium. TDC makes it possible to use standard ferrous steels in place of stainless steel in many applications, including food processing and medical environments.

Value-added benefits of TDC Coating:

- Reduced wear and friction of moving parts. Enhanced corrosion resistance

- No chipping, cracking or peeling from the basis metal

- Improved release characteristics on moulds and dies

- Reduced maintenance and machinery replacement costs

- Smoother, faster and quieter running equipment

- 72 Rc surface hardness Vickers Diamond measurements produce a 1020-1100 hardness rating. Complies to AMS-2438a (10/98)

Specific Applications Include:

- Machine Tools Moulds

- Punching And Stamping dies

- Extrusion Tools

- Engine and Transmission components

- Pump and Meter internals

- Bearings Aircraft Components

- Ball Screws and Linear Slides

- Nuclear Components

What Can Be Coated?

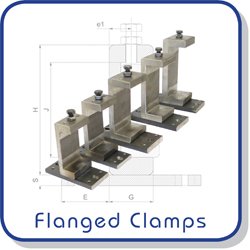

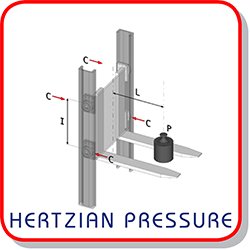

The complete range of Standard Combined Roller Bearings can be coated. This includes bearings, plates, flange clamps and rails.

Furthermore some rails are now available in Stainless Steel. Contact us for further details.

En Français? Voir notre catalogue ici.

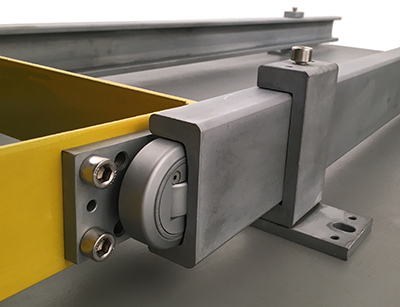

A special combined roller bearing & mounting plate assembly - thin dense chromium plated for use in a salt water environment.

Jumbo combined roller bearing with thin dense chromium plating and oilamid rubbing block

Related Products and Links