APPLICATION & DESIGN EXAMPLE -

TWO STAGE SYSTEM

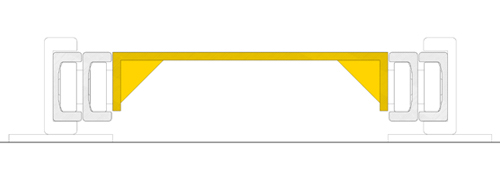

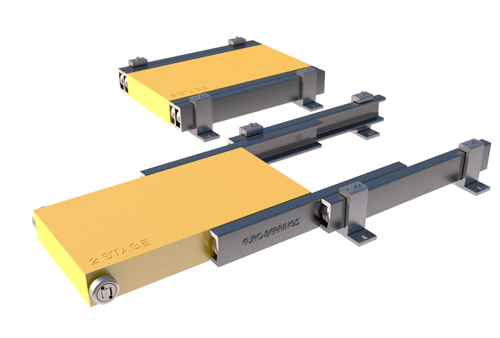

A two stage cantilevered system offers all the same benefits as the horizontal cantilevered system, but in addition it allows the carriage (shown in yellow) to pull all the way out telescopically. Consequently when the system is fully extended, it is twice its original size.

This system requires 2 sets of combined roller bearings & rails (i.e. 8 bearings & 4 rails). In this diagram an extra bearing is shown on the front of the carriage - this provides added strength to the carriage when the system is packed away.

The bearings can be supplied pre-welded to a mounting plate and then simply bolted onto the structure, or they can be welded directly to the structure (as shown). The advantage of the mounting plates is that they make maintenance easier but the drawback in a multi-stage system is that they take up more space laterally.

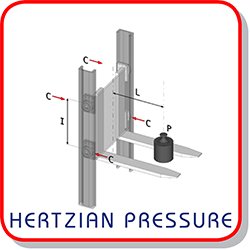

This two stage arrangement can also be used vertically to form a mast. Forks can be added to make a forklift truck or a platform to make a goods lift.

For ultra heavy systems, see our Jumbo combined roller bearings.

Read our technical information on Combined Roller Bearings or view other application examples.

En Français? Voir notre catalogue ici.

Related Products and Links