HOME > MAST BEARINGS > IDENTIFICATION

FORK TRUCK MAST BEARINGS: A guide to Indentification & Terminology

What is a Mast Bearing?

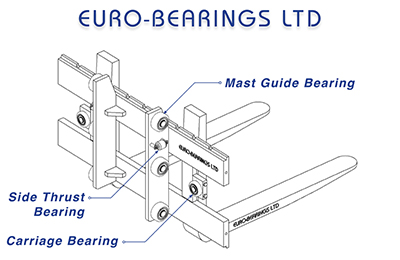

Mast bearings are found on fork lift trucks. They carry the forks (carriage) up the mast and they also enable the various stages of the mast to extend.

There are four main types of Mast Bearings:

|

Sometimes the mast guide bearings and side thrust rollers are fitted as a complete assembly, known as a Combined Roller Bearing.

What properties does a Mast Bearing have?

- Thick Outer Ring: Mast bearings operate at relatively low speeds. They travel along the rail as a track bearing (like a wheel) and consequently experience high loads. The outer ring (steel tyre) of a mast bearing is much thicker than a standard bearing, to enable this load to be transmitted.

- Inseparable Design: The components of the bearings are held together to form an inseparable ‘wheel’.

- Balls or Rollers: Due to the high loads, mast bearings usually have balls or rollers as their rolling element.

- Seals: Mast bearings are usually to sealed to prevent the grease from escaping and to keep debris out. The seal can be rubber (RS) or metal (ZZ), or sometimes a combination of both (ZRS).

What information do I need to identify a Mast Bearing?

Our Technical Sales team are very experienced at identifying mast bearings.

|

|

If the bearing you need is no longer in production or you have a special requirement, Euro-Bearings Ltd can manufacture bespoke mast bearings to suit your needs. Typically we would need a sample or pattern to quote and lead times can be as short as 24 hours.

What if I can not get all of this information?

Get as much information as you can and contact us. We will do our best to help.

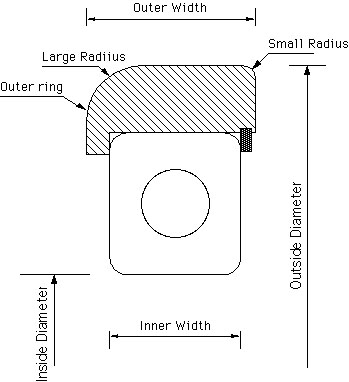

Parts of a Typical Fork Truck Mast Bearing:

|

Glossary of terms relevant to Fork Truck Mast and Carriage bearings

BORE - see I.D. (Inner Diameter)

CAGE - device holding balls, needle rollers or cylindrical rollers apart between inner and outer rings.

CHAMFER - short straight line connecting 2 points across the corner of a bearing (to remove sharp corner).

CYLINDRICAL ROLLER - roller bearing using steel rollers that are less than 3 times their diameter in length. e.g. a roller 3 x 5 is a cylindrical roller but a roller 3 x 9 is a needle roller.

ENDCAP - Cap that blanks off one end of the bore of the bearing.

FULL COMPLEMENT - bearing without cage. Usually higher loadings than caged type bearing of same size and type.

I.D. - Inside diameter of bearing - see drawing above.

INNER RING - smaller of the two rings that form the bearing.

INNER WIDTH - The measurement through the inner ring. See drawing above.

I.W. - see Inner Width

NEEDLE ROLLER - roller bearing using steel rollers that are more than 3 times their diameter in length. e.g. a roller 3mm x 9mm is a needle roller but a roller 3mm x 5mm is cylindrical roller.

O.D. - Outside Diameter of bearing. If the bearing tapers on the OD then measure both largest and smallest diameters. See also Taper.

OUTER RING - larger of the two rings that form the bearing.

OUTER WIDTH - the measurement across the outer ring - see drawing above.

O.W. - see Outer Width

RADIUS - part of a circle around corner of bearing ring connecting outer surface and side surface - see drawing above.

SEAL - usually natural rubber or nitrile rubber seal on sides of bearing to retain grease and to exclude dirt.

SIDEPLATE - usually steel plate with circlips or O-rings inset to seal bearings and to exclude dirt.

SPHERED O.D. - outer of bearing has a part of circle starting at one corner and finishing at the other. Radius is usually big and sphere sometimes difficult to detect. Use straight edge of ruler across OD of bearing.

TAPER - A long straight line connecting two points on the outside surface of the bearing. Commonly, we use this to mean one of the running surfaces of the outer ring, which will run in or on the mast channel. Do not confuse with Chamfer.